The electric vehicle (EV) adoption surge has necessitated a parallel evolution in EV infrastructure. A critical yet often underappreciated component of this development is the underground installation of utilities crucial for powering EV charging stations. Enter directional boring, a sophisticated method essential in paving the way for a sustainable future.

This article explores the impactful role of directional boring, or horizontal directional drilling (HDD), in laying the groundwork for the burgeoning EV revolution.

Table of Contents

ToggleCase Study

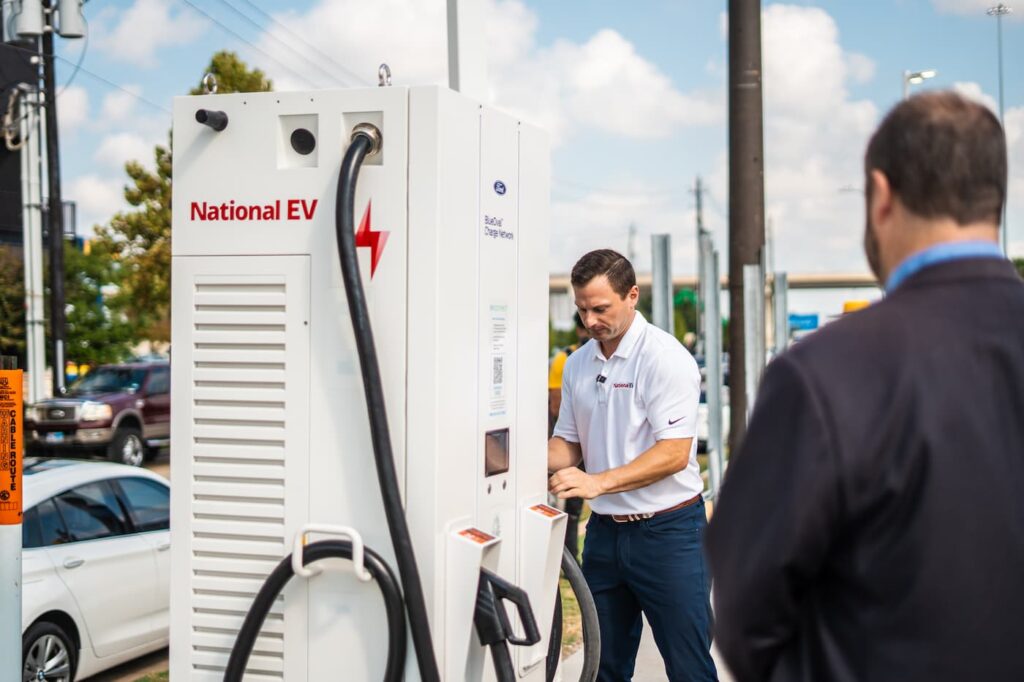

Directional boring played a critical role in a recent large-scale EV installation. The scope of the project was primary power from an Encore pole to a pad-mounted transformer. Traditional trenching was not possible because of existing concrete and utilities that were nearby, including communication lines, water, and sewer.

So what is the answer? Directional boring. This technique allowed the crew to lay the main line’s conduit without disrupting existing structures. It showcases directional boring’s efficacy in navigating challenging urban settings.

Understanding Directional Boring

Directional boring, also called horizontal directional drilling (HDD), is a trenchless method. It installs underground utilities like conduits, pipes, and cables. The minimal disruption this method employs on the surface environment makes it stand out.

Why Choose Directional Boring Over Traditional Methods?

The traditional trenching methods are invasive since long open trenches have to be dug all the way to the laying out of the utilities. This technique interferes with traffic and rips landscapes apart, among other interferences, which can also destroy underground structures.

Moreover, directional boring requires a small starting pit and an exit pit at the end of the planned underground path. Besides, this only needs a small surface footprint.

The Process of Directional Boring

- Planning and Mapping: It starts with elaborate planning and mapping the proposed route below the earth’s surface. This involves studying the soil conditions, existing underground utilities, and other environment-related factors.

- Drilling the Pilot Hole: A small pilot hole is then drilled into the ground through a process known as directional boring. This forms an initial bore of a set diameter. Advanced tracking equipment keeps the initial bore strictly on the planned underground path and guides the drilling process for accuracy.

- Enlarging the Hole: After completing the pilot hole, the next step is to enlarge it to a size suitable for the utility installation. This is achieved through a process called ‘back-reaming.’ This occurs when larger cutting tools are pulled back through the pilot hole, gradually increasing its diameter.

- Installing the Utility: With the hole at the desired size, the utility (be it a pipe, conduit, or cable) is then pulled through this newly created underground tunnel.

The Role of Directional Boring in EV Infrastructure

In the world of EV infrastructure, directional boring offers an efficient green way of either tunneling or drilling horizontally to install electric conduits necessary for EV charging stations. The following reasons distinguish it from all other methods:

- Environmental Friendliness: The process significantly reduces the disturbance to the ecosystem, making it ideal for environmentally sensitive areas like wetlands or regions with protected vegetation.

- Reduced Surface Disruption: The use of directional boring exhibits minimal disruption to landscapes, roads, and existing structures, making it friendly to a community.

- Enhanced Safety: Unlike large-scale excavation, the method eradicates the risk of causing accidental damage to the existing underground utilities, enhancing the safety of the workers and the community.

- Efficiency and Flexibility: Directional boring is efficient and offers the flexibility to navigate obstacles that would be problematic for traditional trenching.

Challenges and Solutions in Directional Boring for EV Infrastructure

As much as directional boring has its merits, it also stands to have some challenges, specifically when it concerns sustainable EV infrastructure.

- Varied Soil Conditions: Soils are different and require different digging methods as well as tools for digging. This makes it difficult to adapt to different conditions.

- Proximity to Other Utilities: Urban areas are packed with existing utilities. Drilling may damage these and cause safety hazards as well as costly repairs.

- Precise Alignment Needs: Accurate drilling is crucial for resource efficiency and infrastructure integrity.

Solutions

- Thorough Pre-Project Planning: The use of geological surveys and 3D mapping is pivotal. They help understand the kinds of soil and locations of other existing utilities.

- Advanced Technology for Subsurface Mapping: Ground Penetrating Radar (GPR) tools offer digital surveys. They help identify obstacles beneath the surface.

- Appropriate Equipment Selection: The selection of drilling rigs and bits needs to be based on the soil analysis for effective drilling.

- Continuous Monitoring: Real-time adjustments during drilling maintain alignment and avoid unexpected issues.

- Expertise Utilization: Skilled operators and workers aware of this technique should be in charge of executing this.

- Regulatory Compliance: Conforming to environmental regulations and obtaining permits helps protect local ecosystems and stay in compliance with the law.

These are the strategies for successful direction boring in diverse environments.

Conclusion and Future Outlook

In conclusion, directional boring is not just a method; It’s the way toward a safer, more efficient, sustainable green future in EV infrastructure development. The higher the demand for EVs, the more the need for innovative methods. These innovations create a stronger and more reliable network of chargers. This technique reduces environmental impact, boosts safety, and offers flexibility. It can be pivotal in the evolution of green transportation.